We often get asked the question, “How do you refuel a Nuclear Reactor?”. It seems like a daunting task, considering that the fuel is radioactive, and you certainly can’t touch it. We’re going to explain at a high level, how Nuclear Power Plants are refueled. Specifically, we are going to look at PWRs (Pressurized Water Reactors). We’ll do a series later on refueling a BWR (Boiling Water Reactor). For the difference between the two technologies, check out this site. They give a pretty good, high level overview of the differences between PWRs and BWRs.

The Difference With Nuclear

Let’s start with one of the key differences that sets Nuclear Power apart from the rest. Plants that burn fossil fuels like coal or natural gas need a constant flow of fuel into the plant. Coal plants generally have rail cars filled with coal, and natural gas plants may have pipelines that allow a constant flow of fuel. Nuclear is very different. With Nuclear Power, sites generally refuel every 1-2 years, depending on the design of the plant. That means that the fuel that is put in the Nuclear Core stays there, and generates a lot of heat for years! That’s a lot of energy!

So if there’s that much energy, there must be a lot of fuel right?

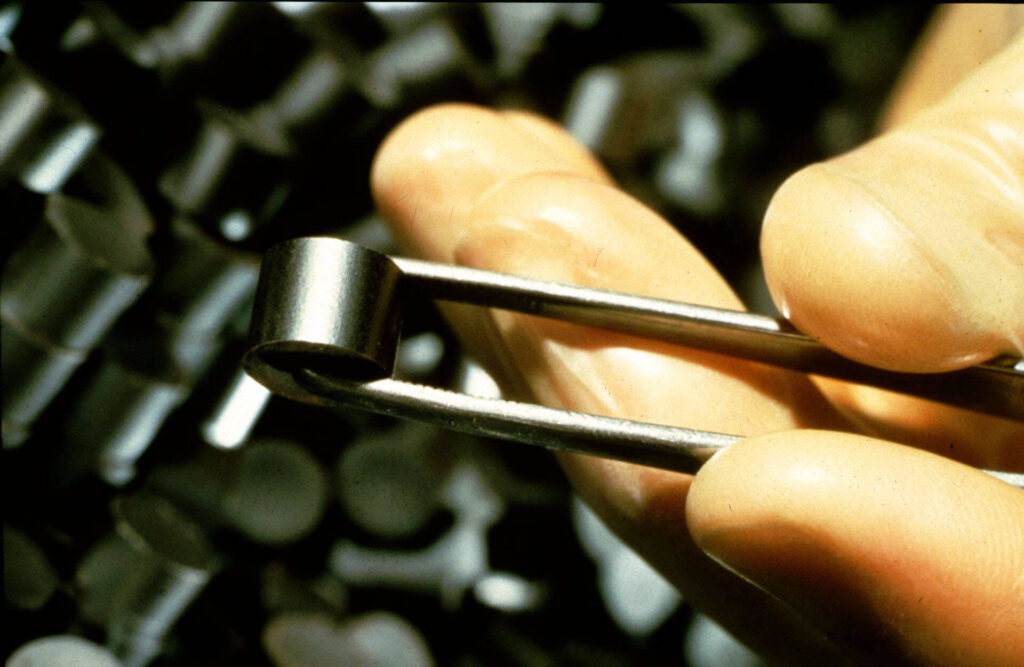

No! Nuclear fuel has an extremely high energy density. One pellet of Nuclear Fuel weighing 0.3 grams (less than the weight of a quarter) is equivalent to roughly 1 ton of coal, 150 gallons of oil, and 17,000 cubic feet of natural gas (Thank you NEI.org for the statistics). Nuclear currently has no equivalent with energy density. That’s why a Nuclear Reactor can go so long without refueling. It’s also why the technology is so important for the Nuclear Navy.

To give you a concept of the amount of energy a reactor has, consider this. Each fuel pellet is about half an inch tall, and about half an inch in diameter. These pellets go into tubes, and are filled to a height of around 12 feet. Each of these rods is then put together into an assembly of around 14 x 14 or 17 x 17 rods (179-264 rods – there are gaps for control rods). And each reactor has about 121-193 fuel bundles. That’s a lot of energy.

Shutting down the Nuclear Power Plant

When a plant needs to be refueled, it first must be shut down. Nuclear plants typically operate for an entire fuel cycle at or near 100% of the rated power output. Generally, the only reason for a nuclear plant to shutdown would be due to maintenance.

Shutting down the plant is the job of Nuclear Power Operators. These operators are some of the most highly trained and talented workers in the world, throughout nearly every industry. Many times, these operators have experience in the Nuclear Navy. These operators first begin shutting down the Nuclear Reactor by going through training in the Simulator.

Preparation, Preparation, Preparation

Nuclear Plants have simulators that simulate conditions during plant shutdown. The simulator is effectively another Control Room, where all of the lights and switches are connected to a computer. The computer simulates the reactor response, and provides feedback to the operators based on what the plant would do. It’s effectively a video game for operating a Nuclear Power Plant.

Operators walk through all of the steps required to shut down a nuclear reactor. This training makes sure that the shutdown can be performed safely, and error free.

Shutting down the reactor is a very controlled process. Operators don’t just hit a button (normally) to shut the plant down. During normal operating, the steam created from the heat in the Nuclear Reactor goes through a turbine which turns a generator to generate electricity (PWRs have Steam Generators, but the heat still comes from the reactor). When the plant is shutdown, the steam flow to the Turbine is throttled (reduced). This reduces the electrical power output, and the heat output of the reactor (reactors follow the turbine load).

Once power gets down to low level, the generator is taken “offline”. This means that the generator is no longer generating electrical power for the grid. Once offline, the plant is tripped. Tripping the reactor causes control rods to be inserted into the core, which stops the chain reaction and the Nuclear Reactor is officially shutdown.

The Story on Decay Heat Removal

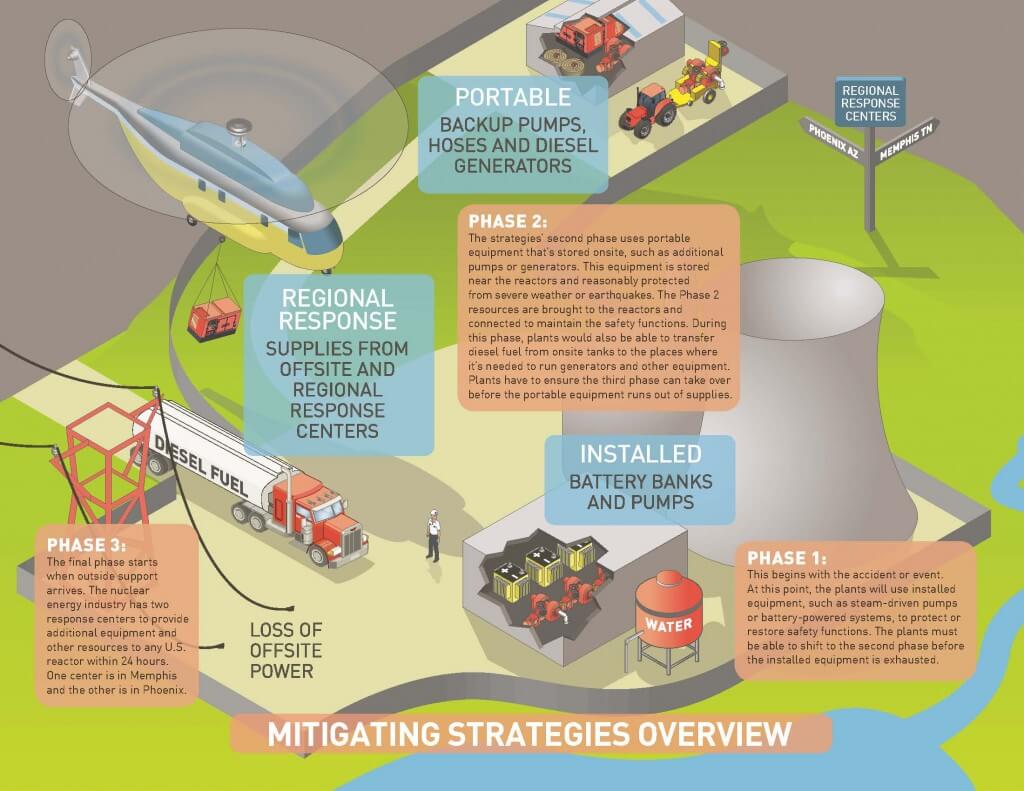

Once the plant is shutdown, the core is still actually making heat, called decay or residual heat. The amount of heat will keep dropping exponentially, but it does have to be removed for cooling. Normally, the heat is used to make steam and turn a generator, but when the generator is offline, we use supplemental cooling systems, namely Auxiliary Feedwater (AFW) and Residual Heat Removal (RHR).

AFW is used to fill the Steam Generators with water. The heat from the core boils the water, and the steam is released to the atmosphere.

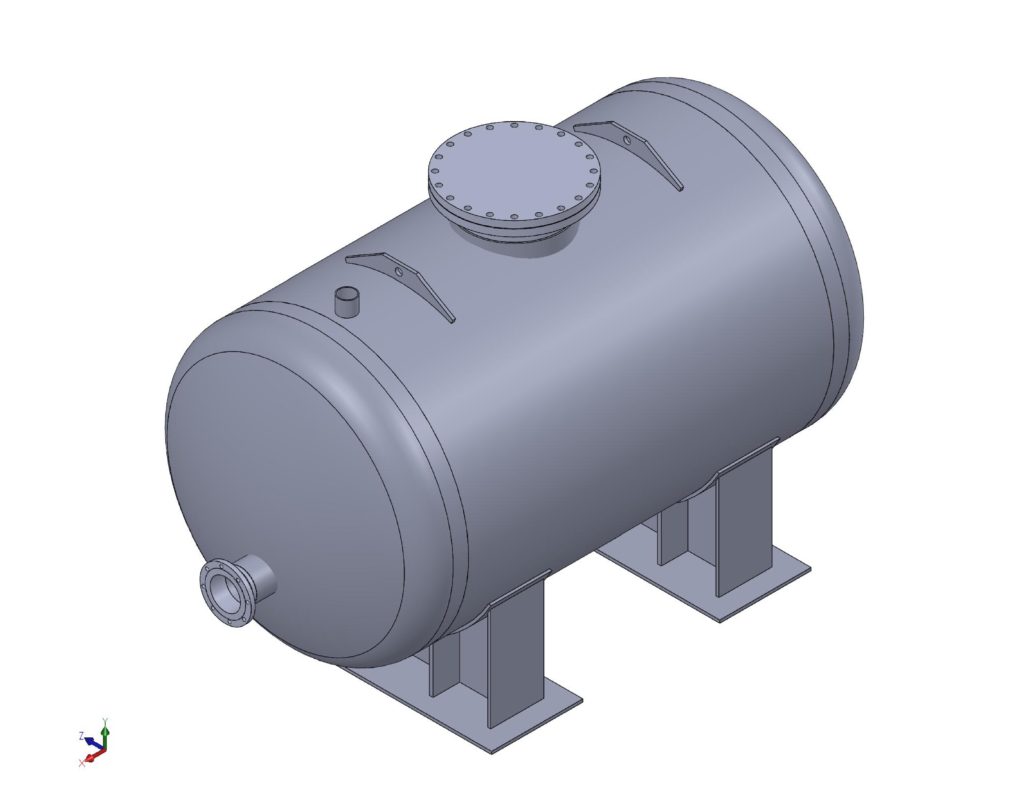

RHR recirculates the water from the core through a heat exchanger, and back to the core. RHR is used only when the core has already been sufficiently cooled and depressurized using AFW.

Lifting The Head

One of the most watched parts of a refueling outage is the lift of the reactor head. After everything has been cooled to well below boiling, and the RCS has been drained slightly (just below the head), the reactor head is loosened, and lifted. It’s likely the heaviest lift that any Nuclear Plan will do in a given year.

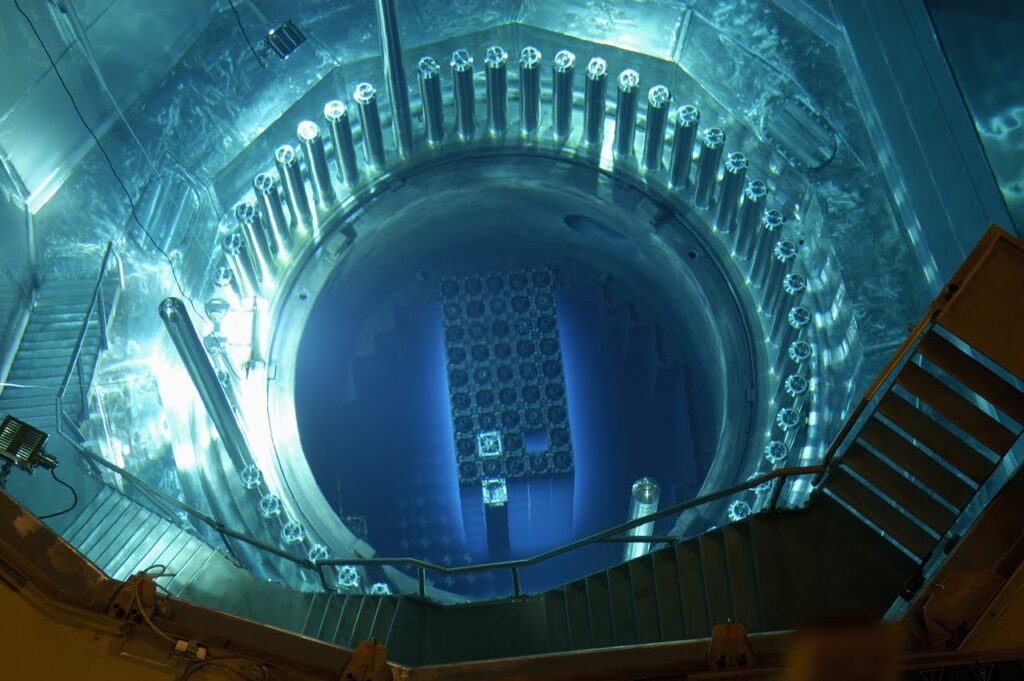

There’s one more important thing to do before the head is lifted. The rods that were inserted in the core to stop the nuclear reaction are in the head, and they need to be detached so the rods stay with the fuel. Those tubes you see in the picture above are where the control rods normally site at power.

During this evolution, there is an increased risk to the plant because the water level has been lowered to get the head off. Once the head is on the stand, operators refill the reactor and the refueling cavity. Once the refueling cavity is filled to the top, the plant is in a very safe state, and minimal supplemental cooling is needed to keep the fuel cool.

Moving the Fuel

At this point in the outage, nearly the entire plant is disassembled and inspected or repaired/replaced. It’s not uncommon for the number of people on-site at a plant to triple during an outage.

While everyone else is doing maintenance, the refueling crew begins refueling. The refueling process, like everything else, is different at every plant, but basically, the fuel is lifted with a crane, and moved to the Spent Fuel Pool where it gets stored. All manipulations are done with the fuel under water.

Typically, plants only refuel 1/3 of the core for each refueling outage.

The new fuel is shipped to the site and placed in the Spent Fuel Pool before the outage. The fuel is the put in the core using the same refueling crane. Nuclear engineers figure out the right positions for everything to make sure the power is properly balanced, and that the fuel is burned efficiently and evenly.

Reassembly

Reassembly of the reactor is basically the reverse of disassembly (again, from a high level). Generally, plants are designed to that refueling the core is critical path. In other words, the rest of the plant needs to be put back together as refueling wraps up so that the plant can begin making power again.

4 thoughts on “Nuclear Reactor Refueling”

At what point in the construction process of a Navy Carrier does the Reactor get fueled?

Thanks for your invaluable explanation. I am curious how long time does it often take to refuel the nuclear reactor? Thanks a lot.

how much radiation is release out of the plant during refueling?

Out of the plant? Shouldn’t be any. The used fuel is kept in water all the time and the water is a very effective shield, so the process is designed for no significant radiation to escape from the water. If there were to be an incident (pretty unlikely, but not impossible), containment would keep the radiation within the structure and none would be released into the environment.

Hope this helps.