Background

Nuclear plants have to design for some extreme natural events, including hurricanes, tornadoes, floods, and seismic events. One of the most challenging to design for is tornadoes because they have little warning time, and the wind and debris forces are incredible.

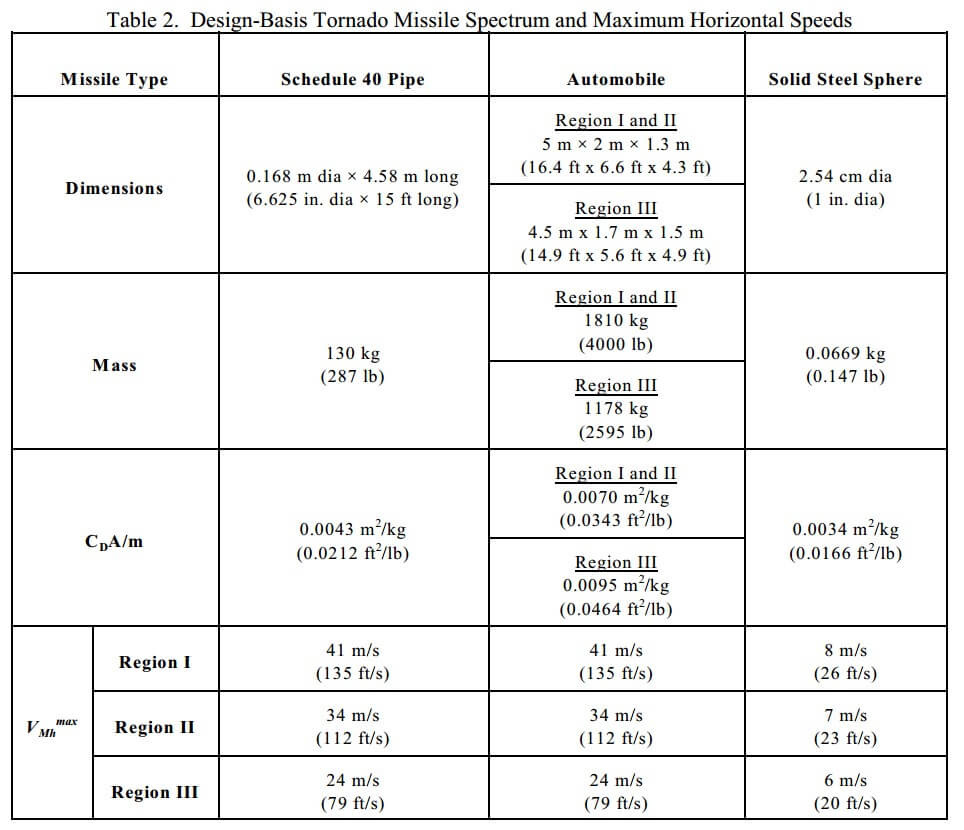

The NRC has a regulatory guide (RG. 1.76 Rev. 1) that describes how plants are supposed to design for extreme events. The guide is very specific, and has the exact debris that needs to be used in design.

If you’re in an area where tornadoes are prevalent, the NRC requires plants to design for a 4000 lb car at 92 mph. That makes for a significant design challenge.

Lessons were Learned

After the Fukushima event, the industry re-learned that extreme events can happen with devastating consequences. As a result, nuclear plant operators made sure that their plants could handle to most extreme events, beyond what they were originally design for.

Missile Barrier Design Review

A plant in Tennessee was working on upgrading protection for tornadoes. One of the many changes being made was additional protection for a water storage tank. The water would be used to cool the reactor if the plant were to experience a natural disaster, and the owners of the plant wanted to build a wall to protect the tank from wind borne debris.

The owner hired an engineering firm that developed a design that used a concrete shear wall to burn up the energy of the missile. The wall had to be thick enough to carry load to adjoining regions.

To ensure that the design was optimized, the owner hired us to review the design to find places to save on cost and construction time. We worked with the prime engineering firm, and we helped find some areas for cost savings.

The original design had a lot of bar, both on the front and back of the wall. Looking closely, we noted that substantial rebar was only needed on one side of the wall because the impact would only occur from one direction (the other side was the tank). We also found some conservatisms at other locations in the wall. Overall, we were able to remove about 30% of the rebar, which also saved on construction time.