Explicit FEA software is a powerful tool to model dynamic structures and transient loading. They are, time-consuming and difficult to troubleshoot. Often, FEA engineers apply simplifications to reduce model size computational expense. It’s essential that these simplifications applied to produce accurate results.

A common error is reducing the model size and scope and forgetting to re-insert the “missing mass” in to the FEA model. Mass is a key parameter in a transient FEA model, an input to inertia, energy and momentum. Missing mass in the FEA model can have a significant, and most likely unconservative effect on the results, consider the following example

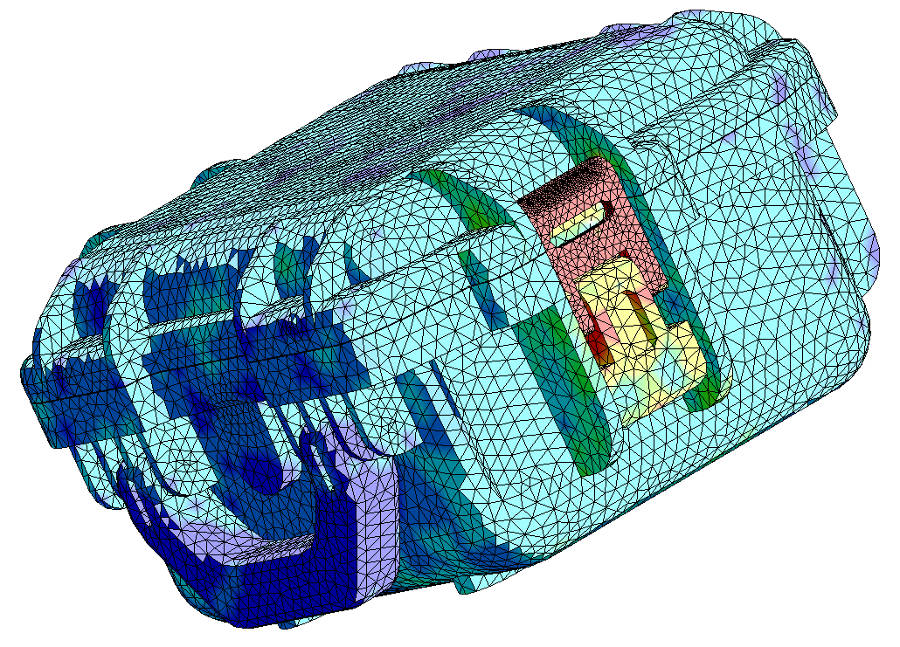

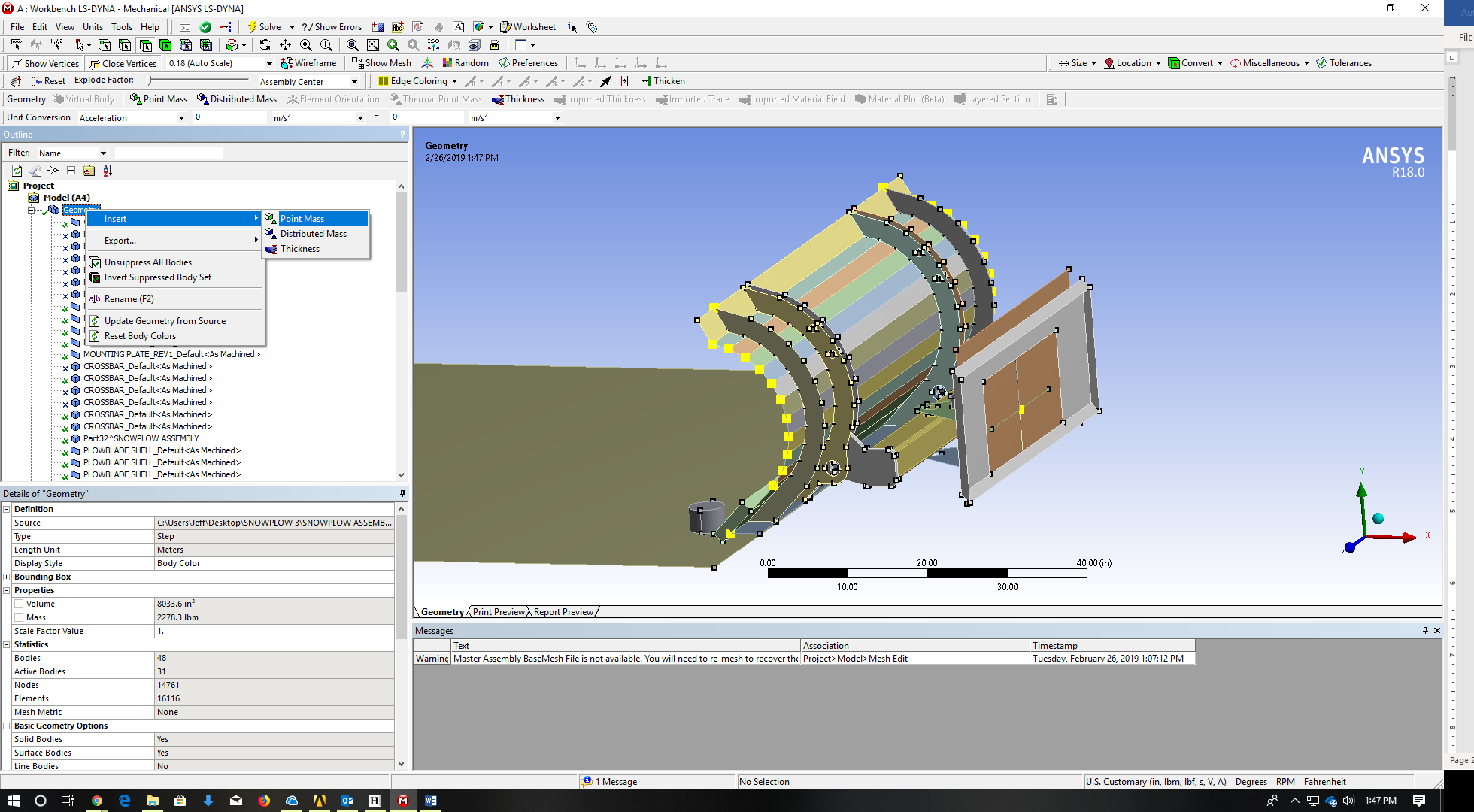

Snowplow FEA Analysis and Missing Mass

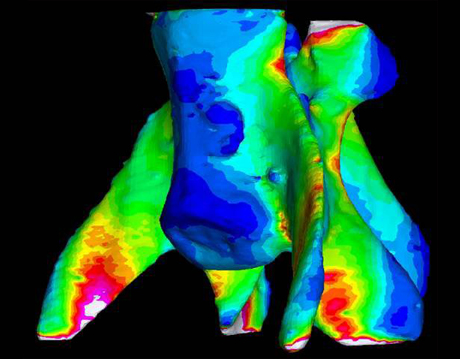

A snowplow is designed to be pushed by a piece of construction equipment. The snowplow must endure continuous loads from pushing and periodic impacts resulting from striking solid objects underneath the snow. Continuous loading and stress analysis can be modeled using implicit-FEA. In this case, the mass of the plow has little effect on analysis except for deadweight. The construction equipment can be replaced by a set of fixed boundary conditions. Load flow and stresses can then be evaluated.

Evaluating stresses from the plow impacting a fixed object can only be completed using an explicit-FEA. In this case the plow traveling with an initial velocity must absorb the energy from striking an object, then rebound elastically. The kinetic energy that the plow must absorb and rebound is a function of mass and velocity. Simplifying the model by removing the construction equipment, has no effect on the initial velocity of the collision. Removing the construction equipment, weight 10 times as much as the snowplow, from the model substantially reduces the mass and kinetic energy in the model. The FEA consultant must ensure that the FEA model incorporates this “missing mass”. Without incorporating “missing mass”

Identifying Disparities

The FEA engineer compares the initial kinetic energy of the model to hand calculations. The kinetic energy of the model is a function of mass and velocity. The initial kinetic energy of the model is 1685ft-lbs. (Plow mass 1400lbm, velocity 6mph)

Using hand calculations, the kinetic energy of the model is equal to 1/2mv^2. In the worked example above, the mass is the sum of the snowplow (1400lbm) and the construction equipment (8000lbm). The construction equipment is not modeled. The plow and construction equipment are subjected to an initial velocity (6 mph). Initial kinetic energy of the system using hand calculations is 11,312ft-lbs.

The FEA model only contains 15% of the energy in the system. The FEA model with less energy places a reduced demand on the structural system. The stresses, and deformations predicted by the FEA model are non-conservative.

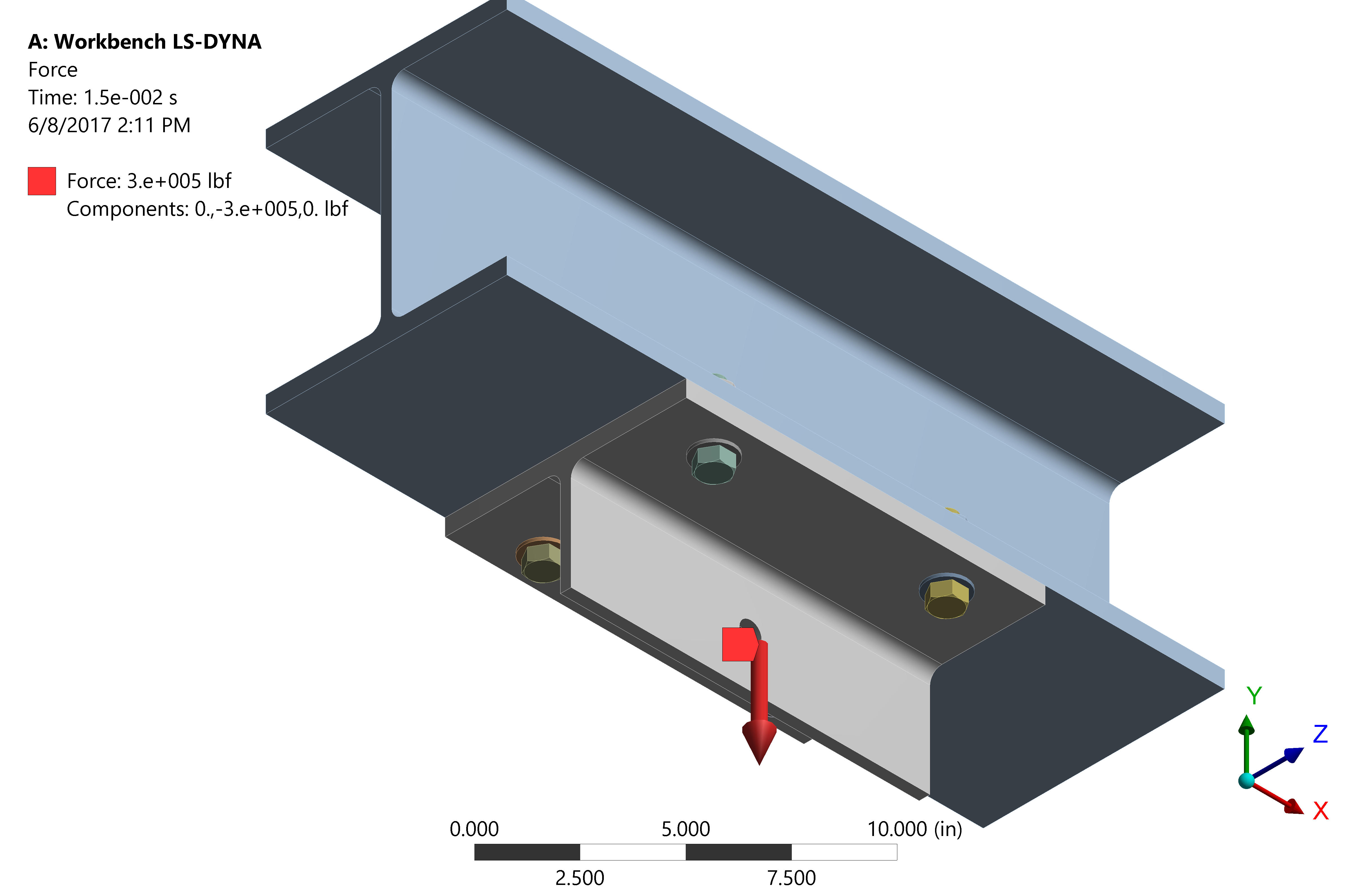

Correcting the Problem

To correct the disparity, the “missing mass” needs to be incorporated into the FEA model. A point mass affixed to the snowplow mounting plate replicates the missing mass. The mass is equal to the weight of the construction equipment.

Contact Us

For more information about our transient Finite Element Analysis services contact one of our FEA consultants at XCEED Engineering & Consulting P.C. at:

585-340-7277