Sometimes the hardest part of a project is answering the question “What is it?” and the immediate follow-up “What is the governing code?”

The governing code and its requirements can have a big impact on project cost and project success.

- Overspecifing Code Requirements: Application of overly-conservative codes results in expensive quality assurance controls. For example, specifying inspection criteria for high-pressure hazardous systems, is overkill for water distribution systems.

- Underspecifing Code Requirements: Application of underly-conservative codes can result in high-consequence failures. For example, specifying inspection criteria for vertical storage tanks isn’t sufficient for the inspection of high-energy pressure vessels

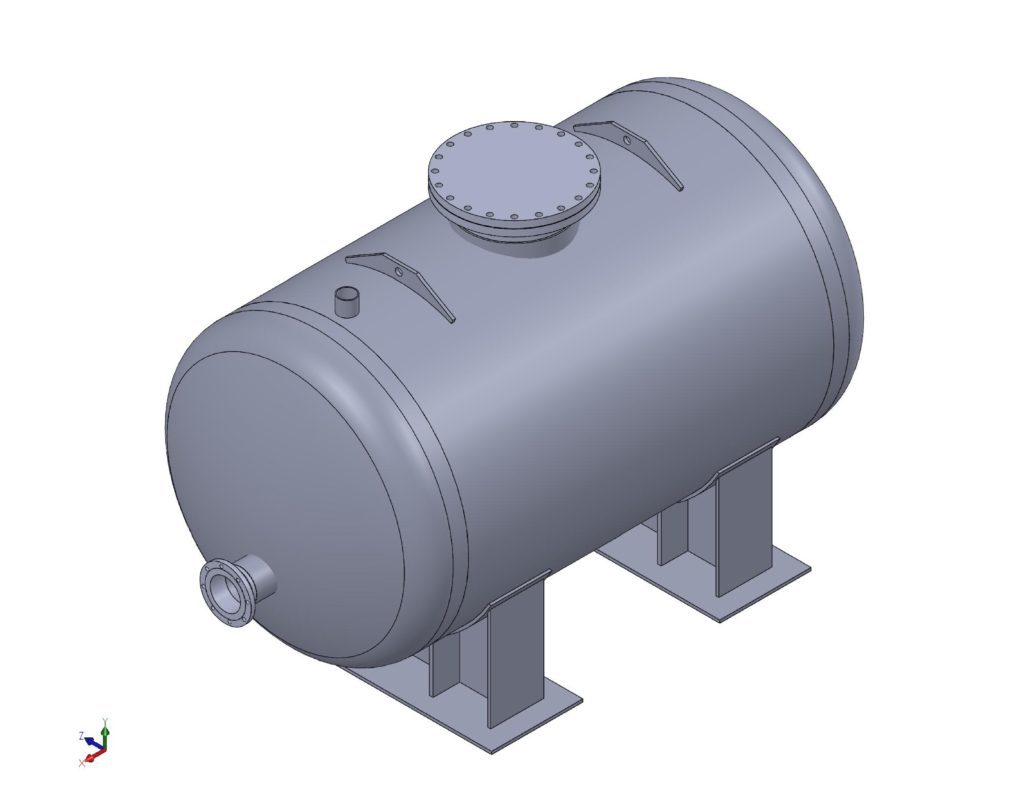

The first step in deciding design requirements is deciding the governing code of construction. We recently quoted the design and fabrication of a small Buffer Tank. This tank is a superb example of how the name of a component may not coincide with the design function or governing code requirements. In this example we’ll discuss how, in terms of the governing code, things aren’t always what they seem. In our example we’ll discuss when a tank isn’t really a tank.

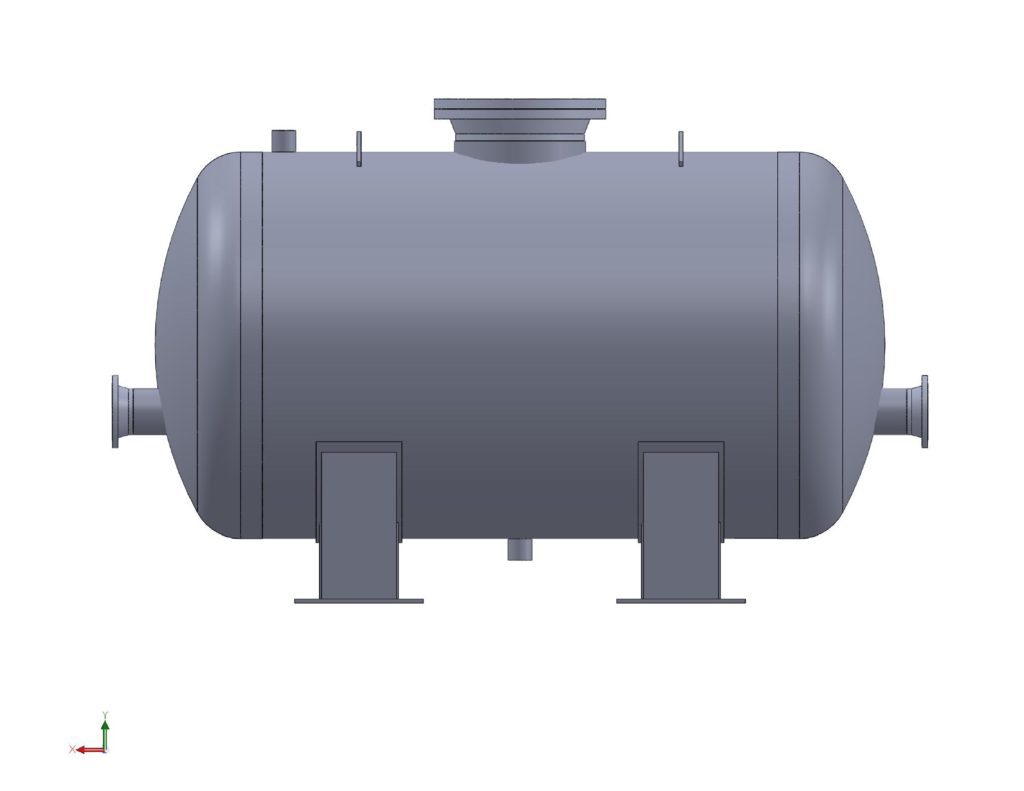

DI Buffer Tank

The buffer tank will increase system chilled water capacity, increasing system heat capacitance. The extra volume promotes stable water temperature control, increasing system reliability by reducing chiller compressor cycling.

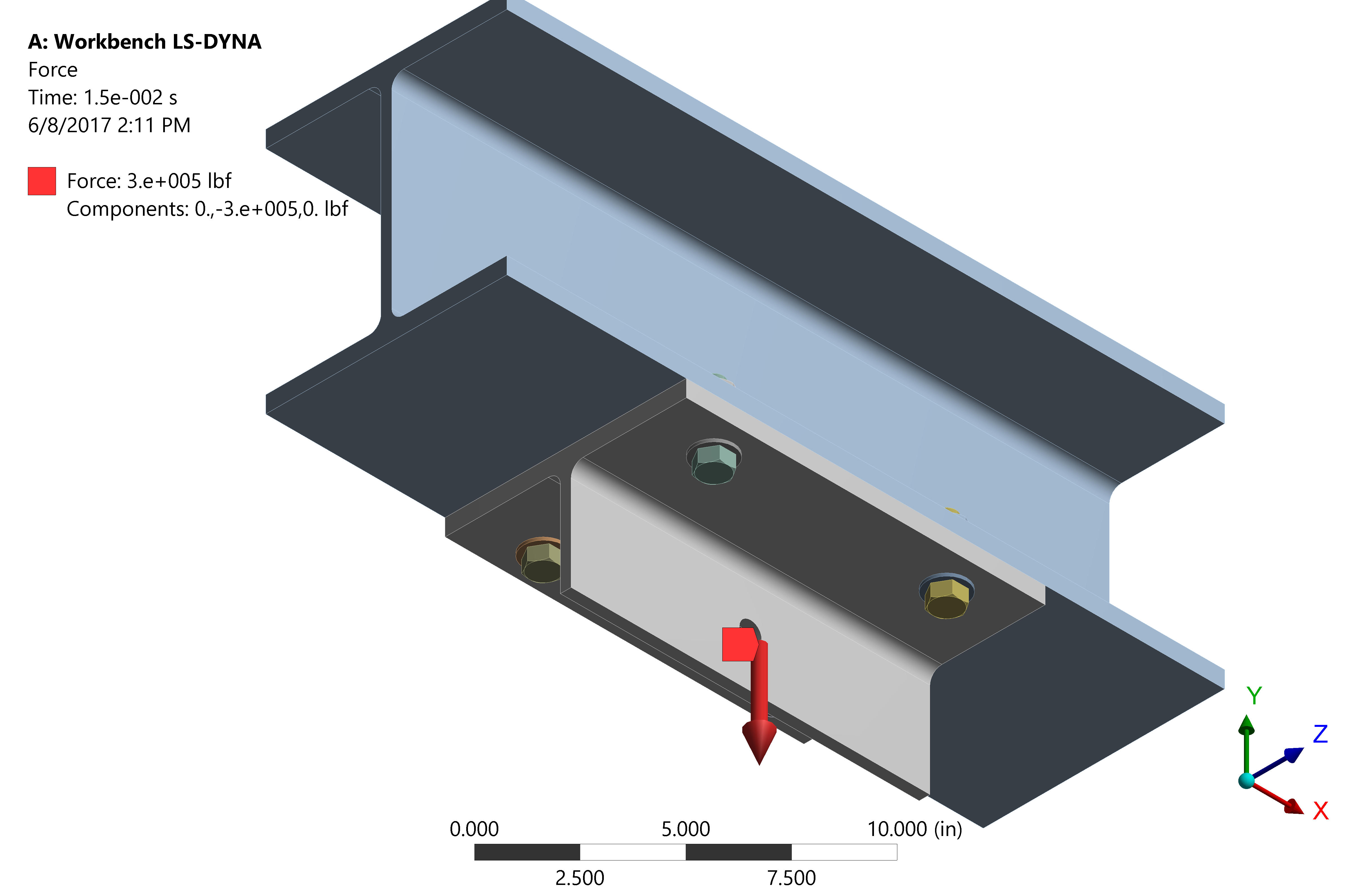

Critical design characteristics of the tank include:

- Nominal Capacity: 1,500 gallons

- Inlet/Outlet Flowrate: 1,200 gallons per minute

- Design Pressure: 150 psig

- Operating Pressure: 15 psig

- Heat Transfer: None

But What’s in A Name, Anyway?

What is the DI Buffer Tank really?

- Is it a tank? Tanks are open to atmosphere and designed for hydrostatic loading. The DI Buffer Tank will be installed in a closed piping system with a 150 psig design pressure. This requirement suggests the DI Buffer Tank is more of a pressure vessel than tank.

- Is it a pressure vessel? Pressure vessels are designed and fabricated under ASME Boiler and Pressure Vessel Code. They bear U-Stamps, affixed by certified manufactures. Pressure vessels are defined within section U-1 of the code. This section notes that Pressure Vessels are not:

structures whose primary function is the transport of fluids from one location to another within a system of which it is an integral part, that is, piping systems;

- Is it just a pipe? The DI Buffer tank is an integral part of the piping system whose primary function is to transport fluids from one location to another. The design flow through the tank is 1,200 gpm. The tank is not expected to accommodate surge volumes or accumulation. Also, there is no significant heat transfer mechanism. The DI Buffer Tank is a large diameter pipe, with the sole purpose to increase system inventory.

Making the Conservative Choice

The arrangement of the DI Buffer Tank suggests it will function more as a large-diameter pipe than a storage tank or pressure vessel.

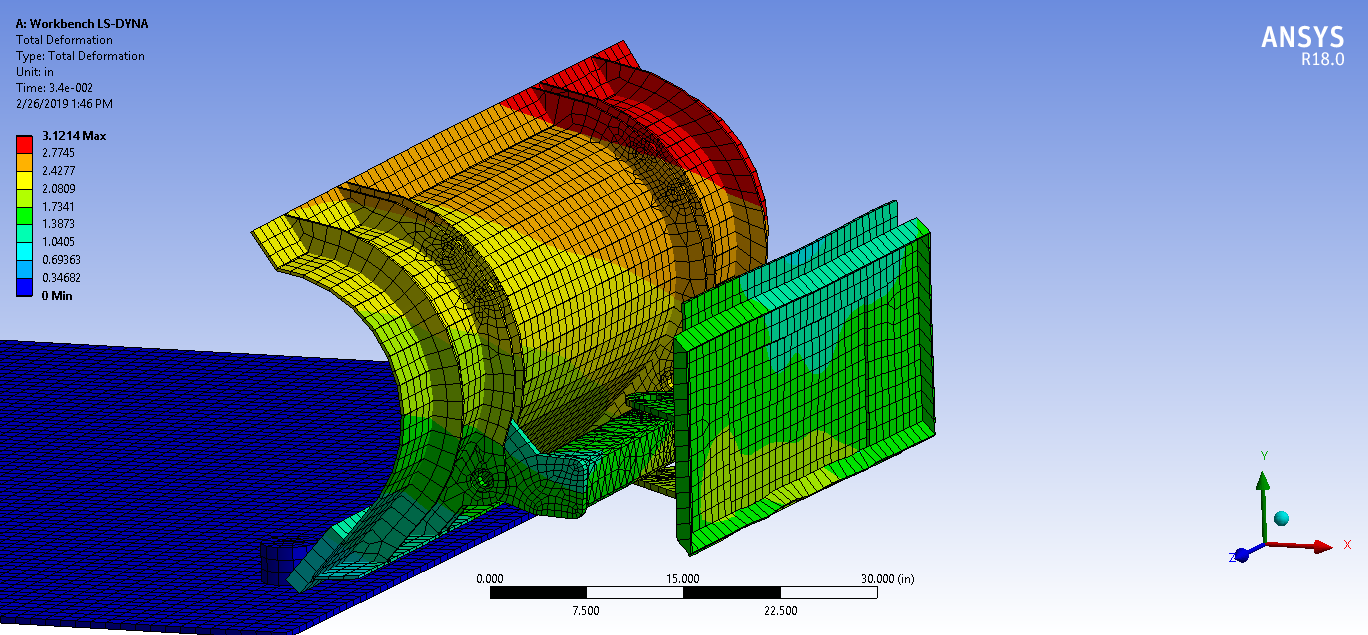

ASME Power Piping codes are based on the application of standard fittings, connections and supports. In the case of the DI Buffer Tank, all nozzles, saddles and endcaps must be custom designed. The ASME B&PV code includes clear guidance for the design of this structure.

The ASME B&PV Code is the best-suited code for the DI Buffer Tank. While the DI Buffer Tank outside the true definition of a “Pressure Vessel” the B&PV permits U-Stamp application, provided the vessel is designed following the code.

Conclusion

The choice of the correct design code for a component is paramount. Design codes specify design, fabrication and inspection controls. These requirements are based on the consequence of failure.

Choosing the correct governing code is not always a simple task. The governing code is based on functions and operational characteristics. Traditional component naming can mask true design functions. In this example, we showed how a tank manifested itself as a pipe.