Background

Nuclear plants undergo a battery of analyses if they want to increase power output of their plant. Increasing the power output influences nearly every component in the plant. These impacts are evaluated in depth before the uprate is approved by the NRC.

Margin can also be effected by plant uprates. After an Extended Power Uprate (EPU), a power plant was challenged with marginal Net Positive Suction Head (NPSH) on the Feedwater Pumps. This low margin could cause cavitation at the pump, which could cause costly damage to the pump internals.

Alternatives

New Pump Impeller

We discussed the option of a new pump impeller with the pump vendor. Based on our discussions, a new impeller was not a feasible solution.

New Pump

A new feedwater pump could have been purchased that did not have the same NPSH concerns. The cost for a new feedwater pump was astronomical. Add this to the time needed to install the pump, and this option was simply not reasonable.

Re-Rate Condensate System

The final option evaluated was to simply increase the pressure at the suction of the feedwater pump by re-rating the Condensate System for higher pressure. By simply throttling some valves, and evaluating the system for higher pressure, we would be able to increase pressure at the Feed pump, and eliminate NPSH concerns.

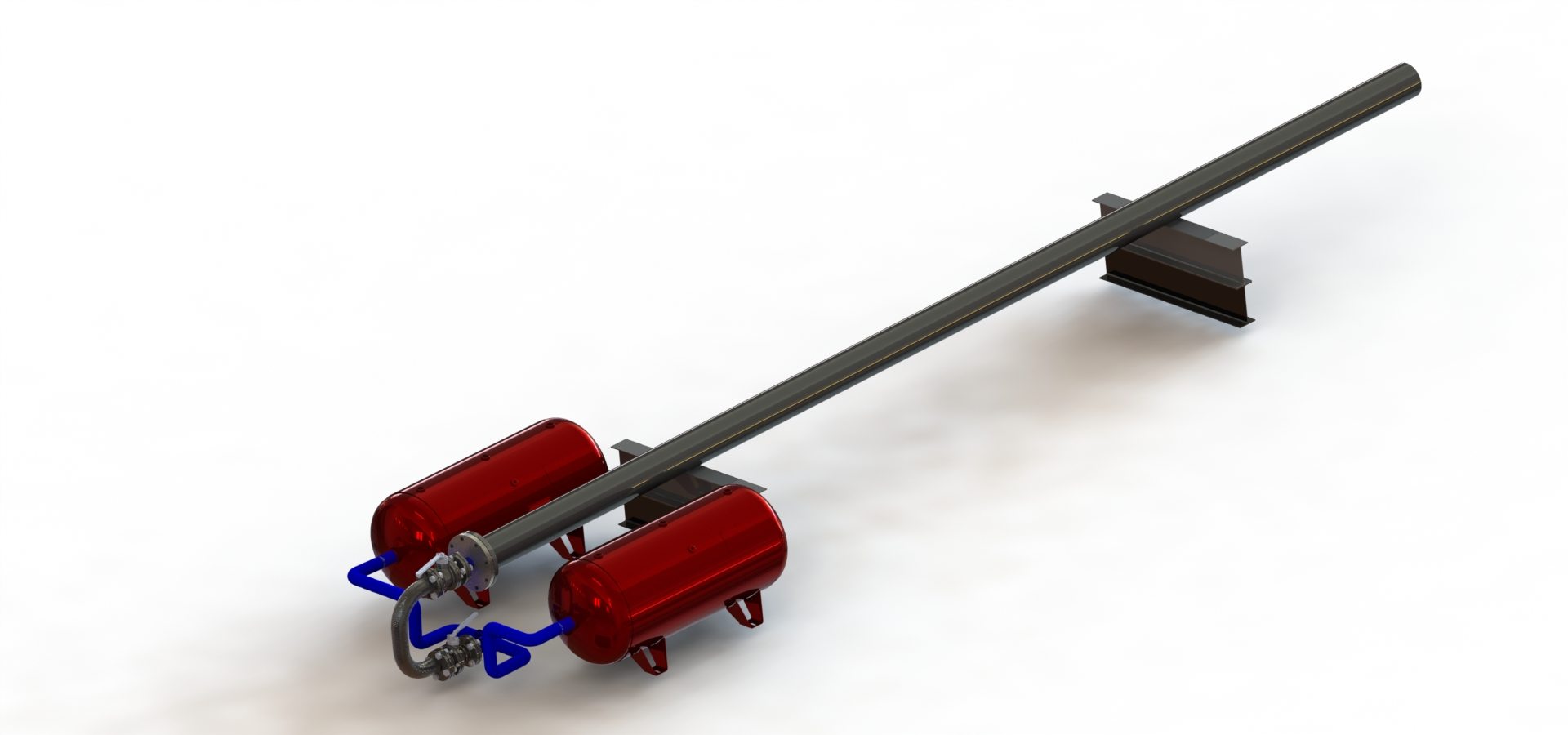

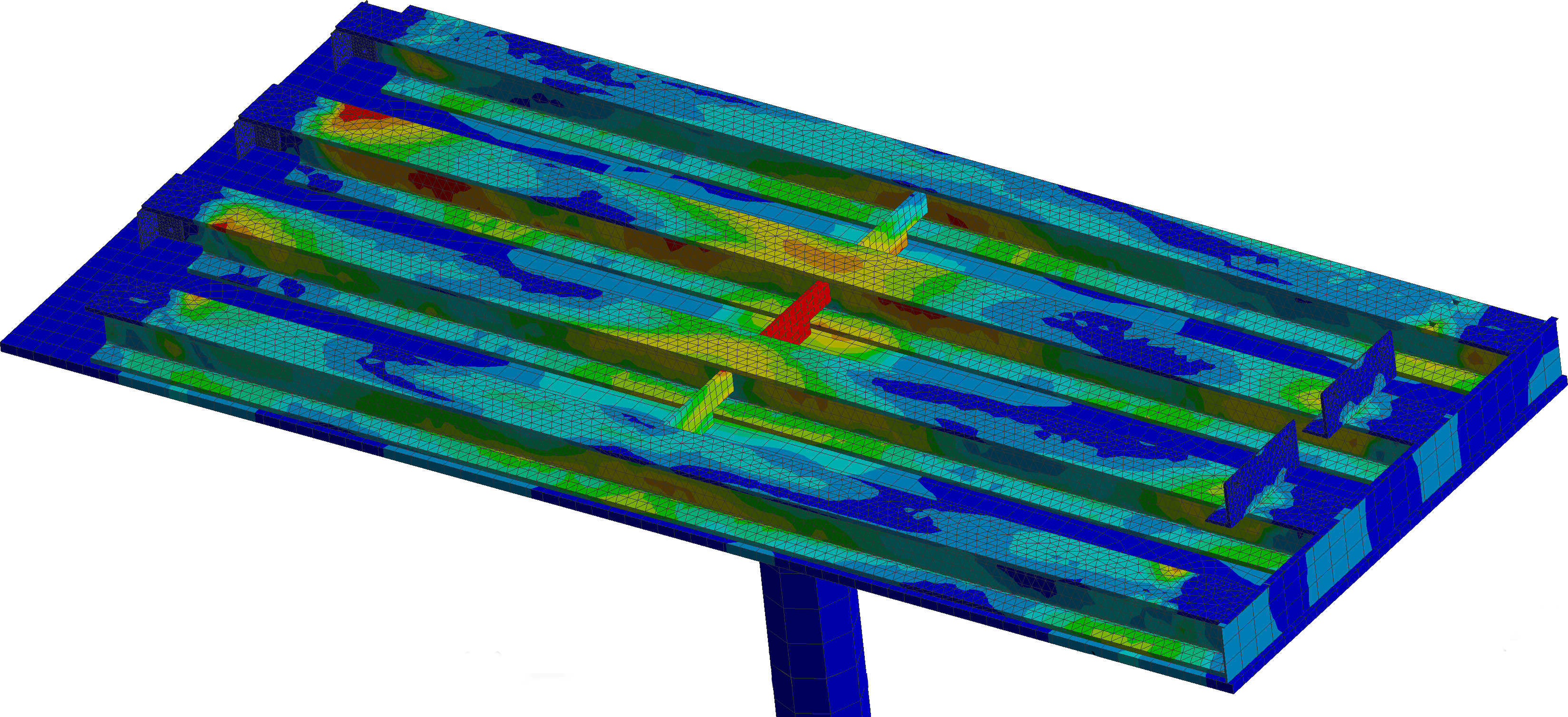

Design

The chosen method was to re-rate the condensate system. Unfortunately, this meant more than just throttling valves. Once the pressure was increased, each component in the condensate system needed to be evaluated for the higher pressure. We found that only a few of the hundreds of parts we evaluated needed to be replaced.

Results

During a refueling outage, the nuclear site was able to replace the limiting parts in the Condensate system, and throttle the valves. The result was a much higher pressure at the suction of the Feedwater pump.