Failures Happen, Learn from Them

If you’ve made it here, something probably went wrong.

And you don’t want it to happen again.

Failure is sometimes inevitable. All we can do is learn from it and fix the issues so it doesn’t happen again. But how do you know what to fix?

When something fails, you need to know exactly why it failed. The only thing worse than not fixing the issue is fixing something that was never a problem in the first place!

The first thing that we do when we’re analyzing the failure is determine the right tool to use. We have an arsenal of tools, including:

- FMEA

- Fault Tree

- Kepner Tregoe

- Why Staircase

No one tool is universal. The failure analysis tool needs to be chosen based on the scenario. Sometimes, using more than one tool is appropriate.

If the failure is extremely critical (e.g. failure of a high risk significant component at a nuclear plant), then make sure an independent failure analysis is performed. Using an independent failure analysis is like a double-blind study. Nobody knows the answer at first, and the results are only reliable if both parties come to the same conclusion independently.

Independent failure assessments lead to highly defendable results. In our experience, if independent assessments are done, regulatory bodies (like the NRC) are much more accepting of the results.

Substantiate Your Claims

Just the facts

The failure analysis is only as good as the facts used to back it up, and experts should be careful to separate fact from opinion.

Recreate the Event

Once the conditions of the event are known, testing and simulation can often be used as a powerful tool in showing how the event took place, and validating how the failure occurred.

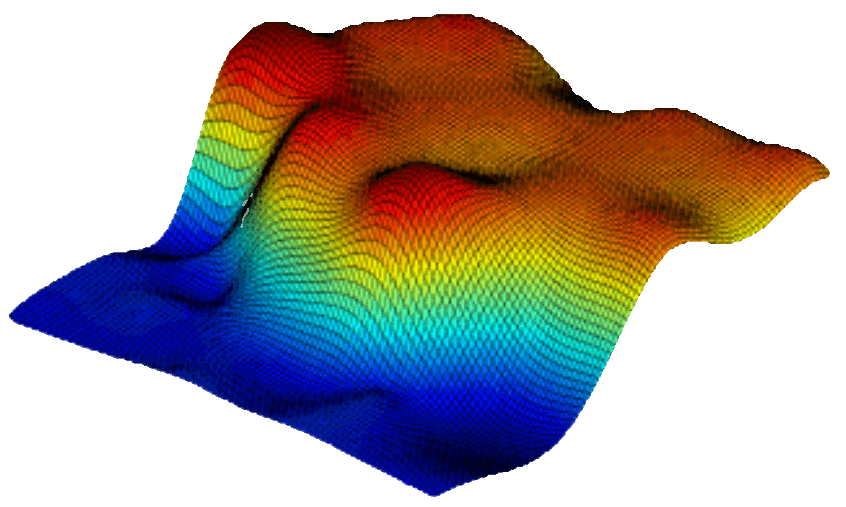

We’ve used Finite Element Analysis, Computation Fluid Dynamics, scaled models, and other engineering techniques to simulate the conditions leading up to failure of components. This is incredibly powerful because it can often be used to prove or disprove all the conditions surrounding the failure.

Expert Witness

If a failure has caused your organization to need an expert witness, give us a call. We’re licensed in New York state, and we’d be happy to provide our expert opinion, backed by formal analysis.

Experience

We’ve outlined some of our recent failure analysis experience below.

- Finite Element Analysis (FEA) is an irreplaceable analysis tool in today’s design process. In the last five to ten years, FEA has emerged as the go-to method to interrogate, test, and perfect designs before physical prototyping. Recent advances in computer technology makes FEA significantly more accessible to smaller engineering firms and manufacturing organizations. Despite this, […]

- Erecting or renovating a steel structure in the modern era typically involves multiple contracted organizations all working together off one set of design drawings. The Engineer, Fabricator, and Contractor hash out design details in a three-way exchange. Using a streamlined structural steel design process can alleviate some of this chaos and the inefficiencies it creates. […]

- Explicit FEA software is a powerful tool to model dynamic structures and transient loading. They are, time-consuming and difficult to troubleshoot. Often, FEA engineers apply simplifications to reduce model size computational expense. It’s essential that these simplifications applied to produce accurate results. A common error is reducing the model size and scope and forgetting […]

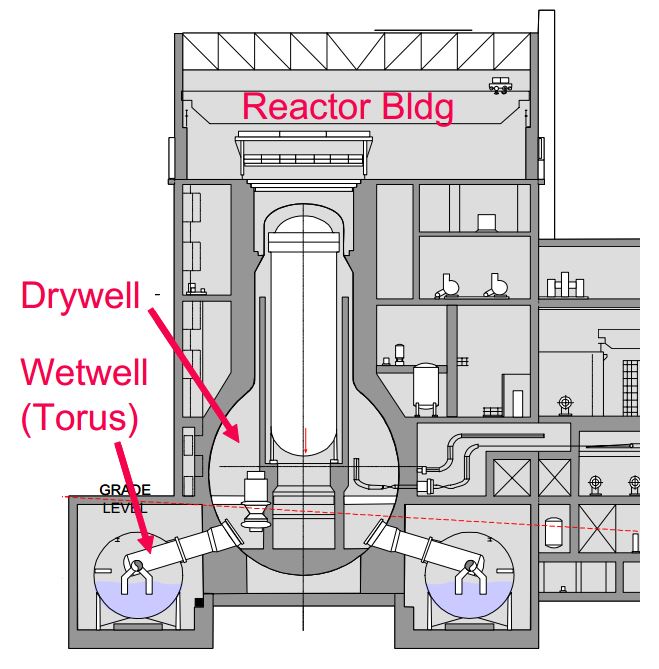

- TI 2515 193 HCVS and SAWM Inspection It’s been seven years since the Fukushima Daiichi Nuclear Disaster. Since then, US Boiling Water Reactors (BWRs) have installed Hardened Containment Vent Systems (HCVS) and implemented Severe Accident Water Management (SAWM) strategies. The NRC will soon inspect licensee implementation using recently developed guidance in TI 2515/193. This […]

- We've looked at dozens of top performers in the engineering field, and gathered these top 5 tips for becoming a successful engineer.

- Explosive hazards are prevalent in many industries. The source of these explosions can be accidental or malevolent. Regardless, site personnel need protection from these hazards. Blast-resistant buildings shield workers and critical assets from blast effects. In this post, we highlight Finite Element Analysis, and its application in the design of Blast Resistant Buildings. In this post we'll cover: Basic blast loading design concepts, differences between hand calculations and FEA, and blast analysis using FEA

- Evaluating Tornado Missiles for RIS 2015-06? We’re going to help make it a little more intuitive. Tornado strikes might not be as bad as you once thought.

- If you’re somewhat new to CFD, you might be asking yourself why there are so many turbulence models. The answer lies at the heart of what CFD software does. It solves the Navier-Stokes Equation as well as the energy and mass conservation. When solving these equations, Prandtl realized that no direct mathematical solution existed for turbulent flow. This has been coined as the turbulence closure problem because the equations can’t be closed for turbulent flow.

- Most structures and their loads are symmetric. In these cases it's possible to take advantage of symmetry to simplify your Finite Element Analysis and reduce run time. In this blog we'll: Discuss benefits of using symmetry in FEA, provide a primer in symmetry theory, and Work through a FEA case study using symmetry.

- Looking for a quick way to find if something will survive a tornado missile strike? Try these calculators for either concrete or steel.

- In last week's blog, we discussed the science behind bolted connections. Specifically their response when subjected to a combined external load and preload. In this blog we'll work through the application of bolted joint science in a finite element analysis. We will: Provide an introduction to FEA modeling of pre-loaded bolted joints, discuss some common troubleshooting techniques, establish methods to validate results of the FEA model and highlight differences between bolted joint science and real-world application.

- You can see them just about everywhere you look. From massive structural steel joints that make up the Golden Gate Bridge to the intricate inner workings of an antique swiss watch, bolted connections dominate our world. Let's take a closer look at the actual science behind the bolted connection.