TI-2515/191 Inspections: What to Expect

The TI-2515/191 inspection for Fukushima FLEX compliance can be a challenging inspection for your site. The NRC will typically send a few inspectors, and the inspection will last the better part of a week. During that time, the NRC is going to inspect by asking questions about your FLEX strategy, so they can gain a better understanding of what your site will do during a BDBEE.

Inspection Trends

When the NRC started their inspections at sites like Watts Bar and North Anna, the inspections focused largely on a tabletop interview with operations personnel. This is a good strategy because it allows the NRC to probe operator knowledge while simultaneously learning about your site strategy so they can better understand it.

Recently, it appears that the NRC has been starting to transition to include more field walkdowns. There’s nothing like a field walkdown to understand the strategy. When inspectors can see pumps, hoses, hose routes, deployment paths, etc., it helps vulcanize the strategy in the inspector’s mind. It also answers a lot of questions before they even come up. Transitioning to perform more walkdowns during these inspections is a good approach, because it benefits both the site and the NRC, because both parties are on the same page, quicker.

Preparing for your inspection

Preparation for the TI-2515/191 inspection is very important for a successful inspection. There are over 800 requirements for Fukushima FLEX in nearly a dozen guidance documents, and even more FAQs. The NRC wants to make sure that every site is compliant, and they can and will point to any one of these requirements, and ask how your site complies.

Our Compliance Matrix Process

Our regulatory consultants have been through many NRC inspections, and we understand the process. That’s why we developed the compliance matrix. The Compliance Matrix is a process that documents how your site complies with each of the 800+ requirements. Your compliance is documented in a database, making it easily searchable, so during your inspection, you can find answers quickly.

We develop the compliance matrix using the same process the NRC uses to inspect your site for FLEX. First, we review your documents and document compliance based solely on your FLEX strategy documentation. Then. we send our team of consultants to your site for 2-3 days, and we focus on interviews and site walkdowns, answering many of the questions that come up during the documentation review. After the on-site audit, we finish our compliance documentation and provide you with the database and a report outlining your site compliance.

Your compliance database that we develop can answer nearly any NRC question. Compliance documentation for each requirement is linked back to the source basis from which the compliance is achieved. This allows the user to get even more information on the topic if necessary.

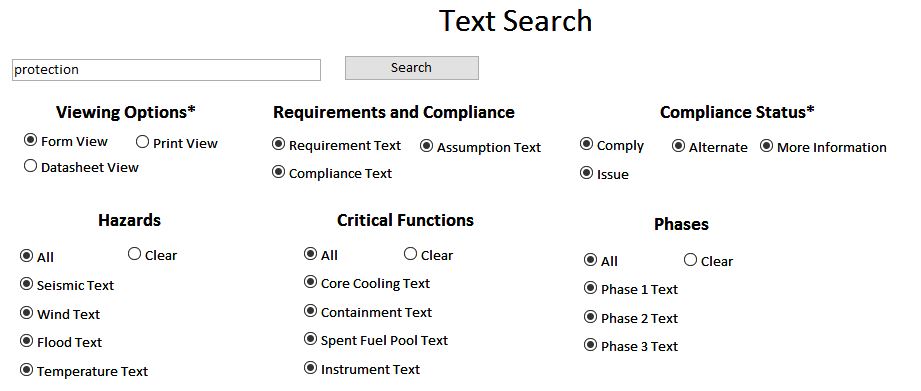

Let’s look at an example. Let’s say the inspector asks how you meet section 7.3.1 of NEI 12-06 regarding equipment separation and protection. There are a number of ways that you can get that information quickly.

1. Search based on Text

You can search terms like “protection” or “separation” on the search page. This will find every requirement that has the text protection or separation.

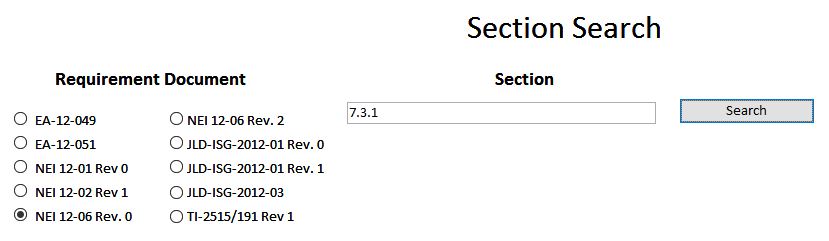

2. Search by Section

If the inspector identified the section, you can search on the section alone.

3. Search by Category

You can search by category. If the inspector asks a broad question, this is a good strategy, because it will show every single requirement remotely related to protection.

Other Benefits

After performing audits and developing compliance matrices for sites across the country, we learned that there are a number of other benefits to using this audit process and compliance tool.

1. Site Alignment

The biggest side benefit is the site alignment. When we develop the compliance matrix tool, we spend 2-3 days on site, performing walkdowns and interviews. Typically, we interview personnel from the following departments:

- Operations

- Maintenance

- Security

- Emergency Preparedness

- FLEX Program Owner(s)

- Engineering

2. Inspector Focus

During the inspection, the compliance matrix itself can be used to help align everyone, including the inspectors on the requirements. Different interpretations are always possible, but the first step in working through these difficulties is understanding the requirement. If a requirement cannot be found in the Compliance Matrix, it’s likely that it’s not actually a requirement.

Webinar

We hosted a webinar on Thursday March 9th to talk about the FLEX inspections. A few of the topics we discussed include:

- Inspection results

- NRC Findings

- Industry trends

- Best Practices

- Inspector Trends – what specific inspectors have identified

- Compliance Matrix process and benefits

- Open discussion

You can view the webinar below. You can click here to view a our Webinar in pdf format. You can also see our Slideshare version of the FLEX Webinar.